RIMS and HERMS explained

The brewing setup that I realised is a so-called HERMS system. HERMS is some instance of a RIMS system. I will explain you briefly what these abbreviations mean and what the advantages are (see also the Links section).

What does RIMS mean?

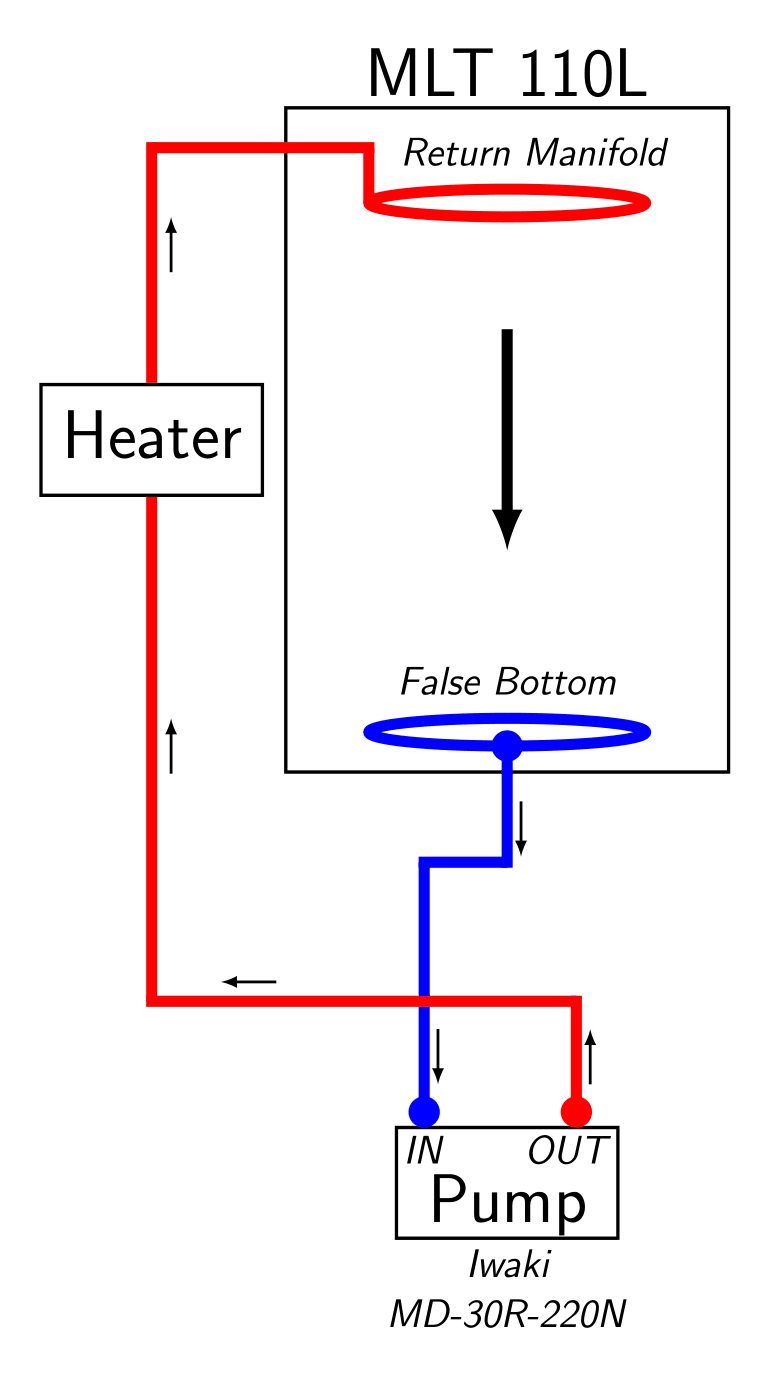

RIMS stands for Recirculating Infusion Mash System. After mashing (adding the milled grain to the water), we let it rest for a while at a certain temperature. The enzymes from the grain convert the starch into sugars. In a RIMS brewing setup, the water is circulated continuously through the grain. This explains the 'recirculating' in RIMS. A pump is therefore an essential component of such a RIMS system. In the bottom of the Mash / Lauter Tun (MLT), a copper filter takes care that the grain remains in the MLT when the (sugar)water is sucked out. The (sugar)water is then pumped back on top of the grain bed. During recirculating, the water can be heated to compensate for heat losses. Some RIMS home-brewers use an electric heating element that is controlled by a PID controller. This controller controls the temperature in the pan by controlling the amount of heat. Another way of heating is by placing a burner under the MLT. But this is not really preferred, since you might scorch the grain (gives a bitter taste). And there is a third way of heating and that is done in the HERMS type of system.

What does HERMS mean?

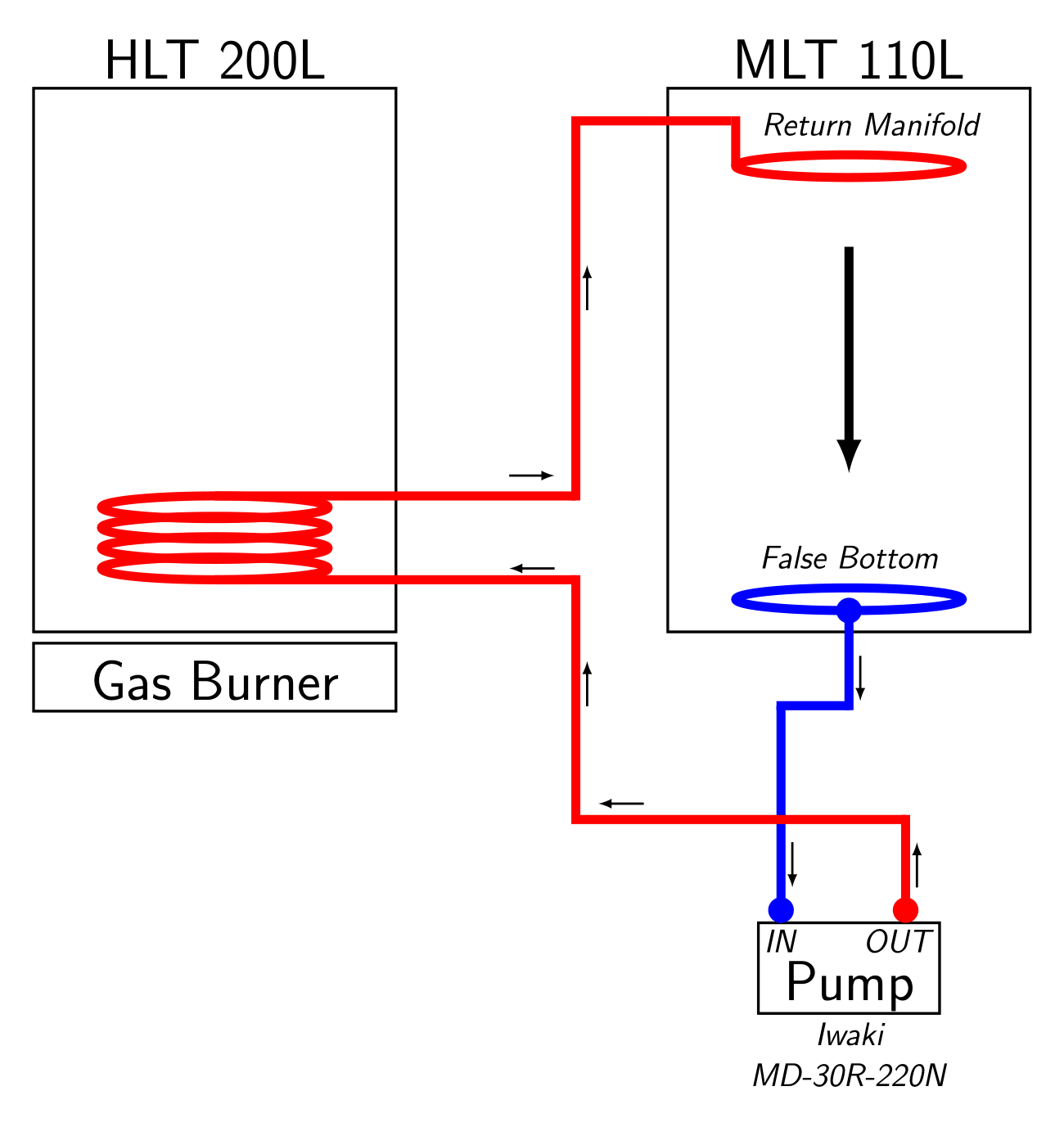

HERMS stands for Heat Exchanged Recirculating Mash System. It is a certain type of a RIMS system. Besides the MLT, we also have a Hot Liquid Tun (HLT), which contains the sparging water. If you add a heat exchanger to the HLT (a long copper spiral), you can then circulate the mash through the heat exchanger. So by heating the HLT, you also heat the mash. And this clearly is an economical way of doing things. In fact you can say that a HERMS system is a RIMS system where heating is done by the heat exchanger in the HLT. By raising the temperature in the HLT, you can increase the MLT temperature. This system has a few advantages:

- The mash water temperature can be controlled accurately

- No direct heating of the MLT, so the grain can not become scorched

- Mash water is clear very fast, because it is recirculated continuously

- The system is efficient and it saves a few hours compared to the conventional system

Back to Top

Back to Top